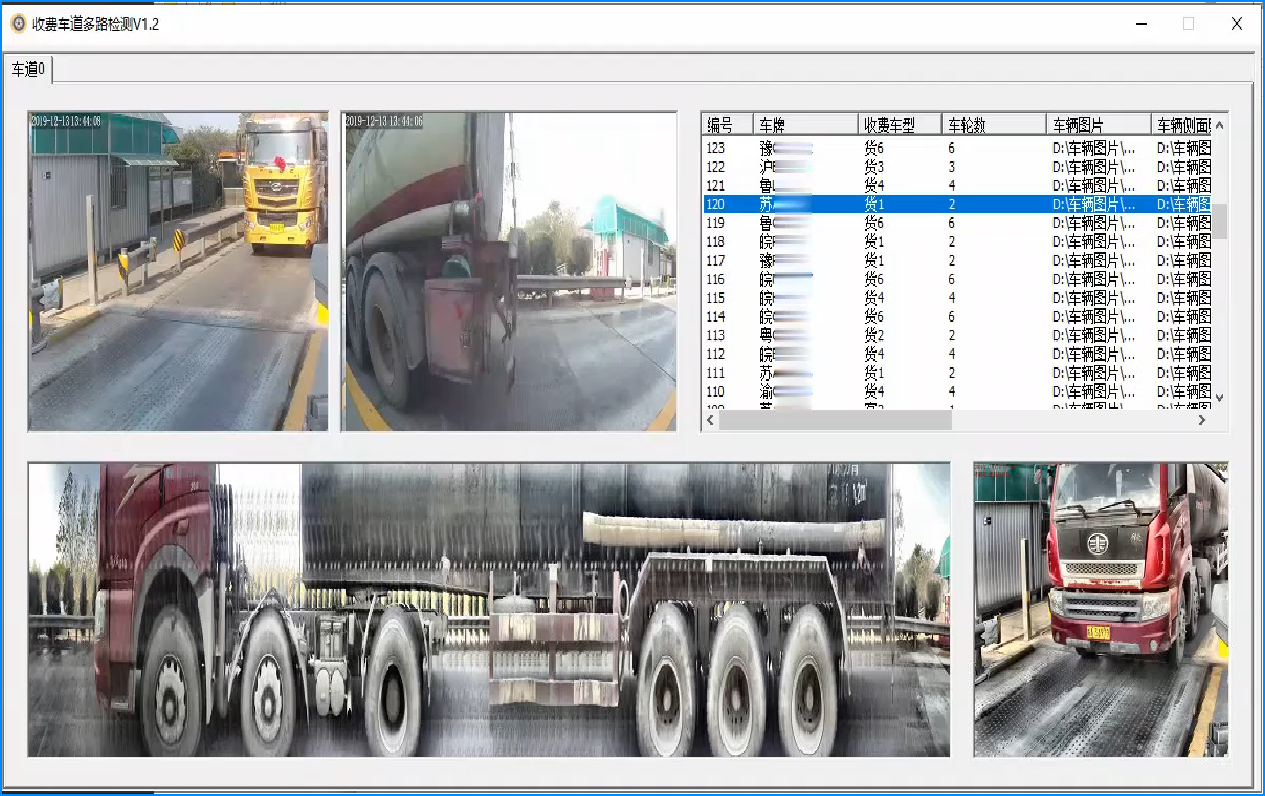

Sistema de inspección de ETC (cobro electrónico de peajes) para autopistas

Soluciones de ETC (cobro electrónico de peajes) para autopistas

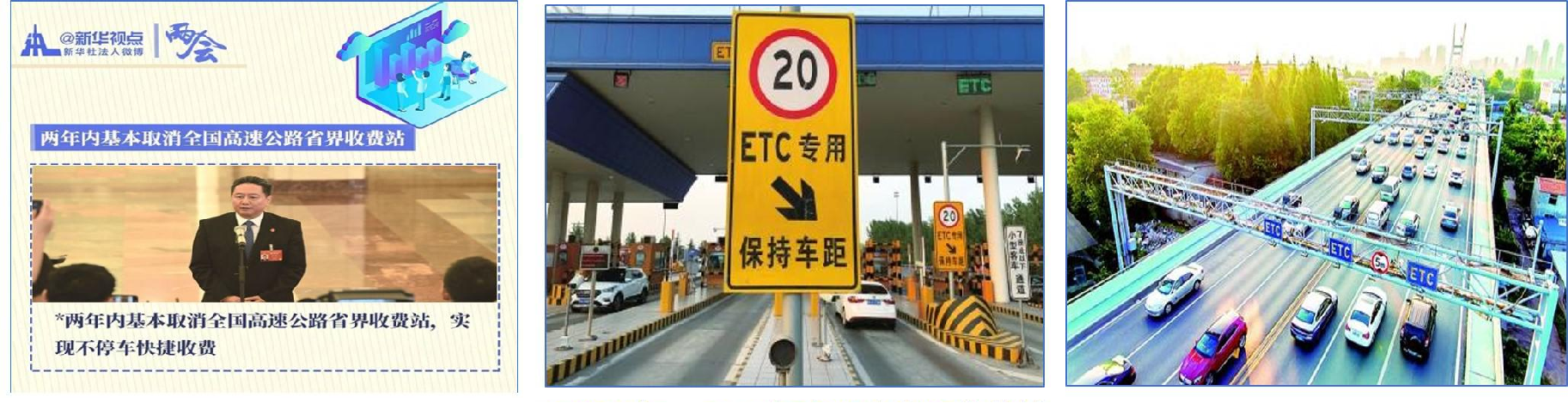

Antecedentes y tendencias

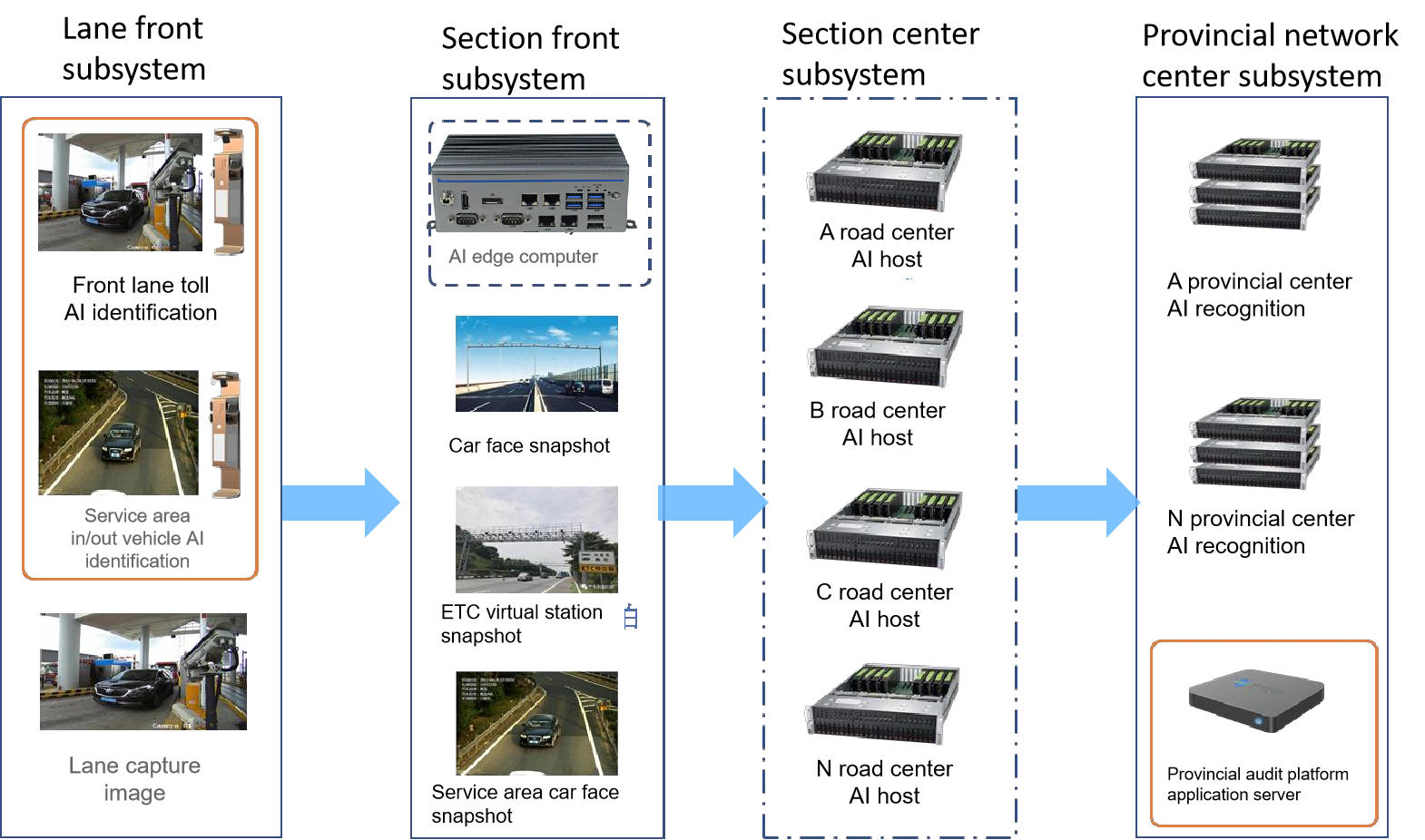

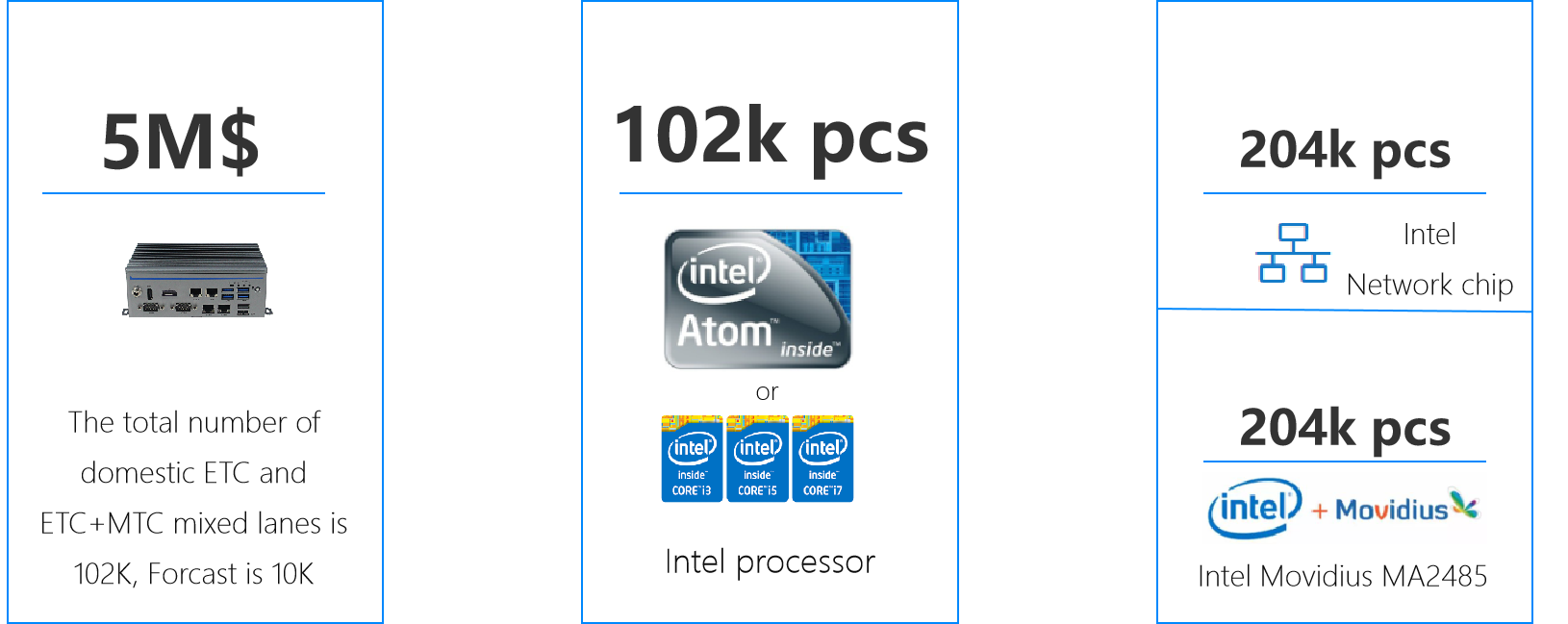

El ETC (cobro electrónico de peajes) se ha convertido en el principal método de cobro de peajes en autopistas tras la implementación del peaje de flujo libre y la eliminación de las barreras de peaje en los límites provinciales. En este contexto, casi 200.000 kilómetros de autopistas en China necesitan actualizarse con un nuevo sistema de cobro de peajes, y cada carril de peaje estará equipado con un sistema de inspección de vehículos. La tecnología de prueba de vehículos correspondiente también enfrenta los requisitos de actualización.

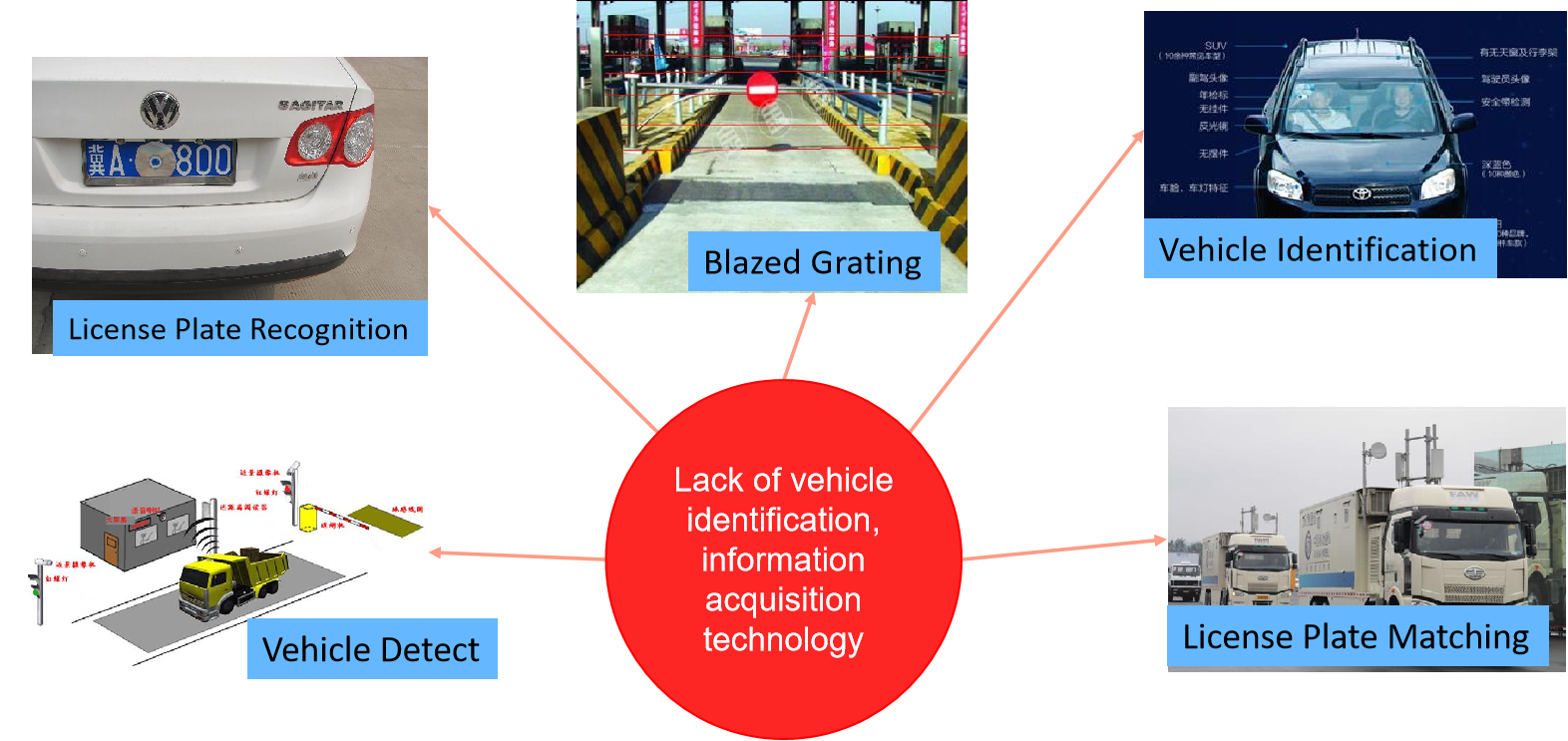

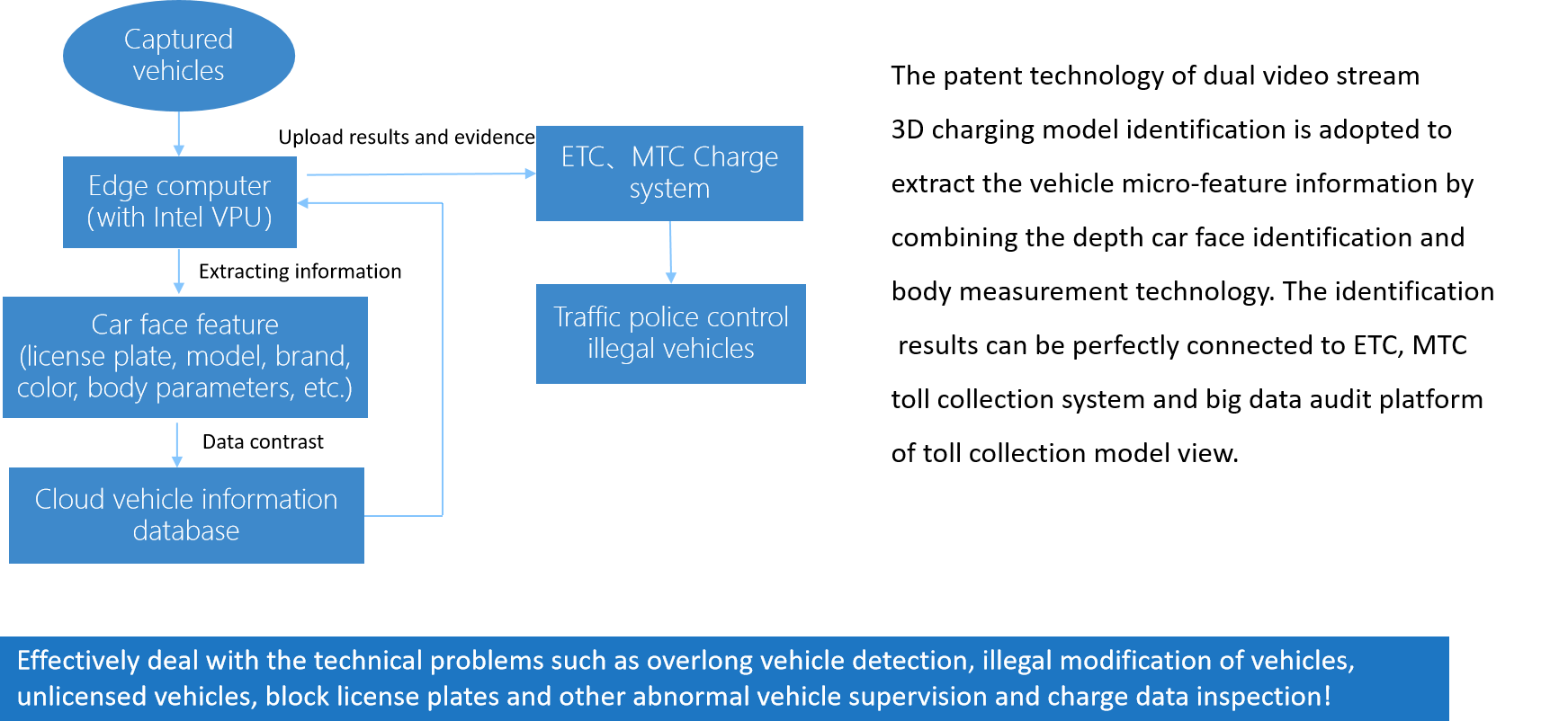

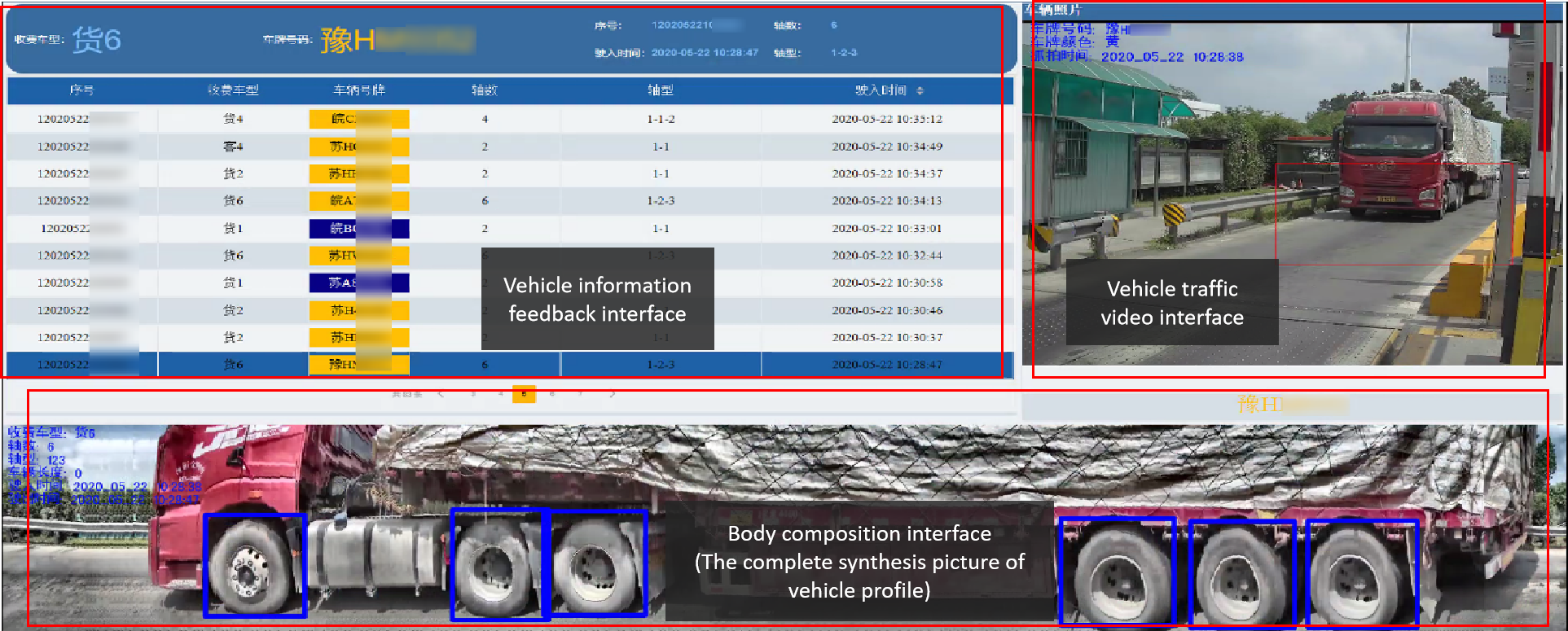

¿Cómo lograr un “reconocimiento preciso de características y una coincidencia precisa del tipo de vehículo” fusionando el reconocimiento facial del automóvil y los datos de las características de la carrocería, y de un “juicio de auditoría artificial” a una “auditoría inteligente de macrodatos”?

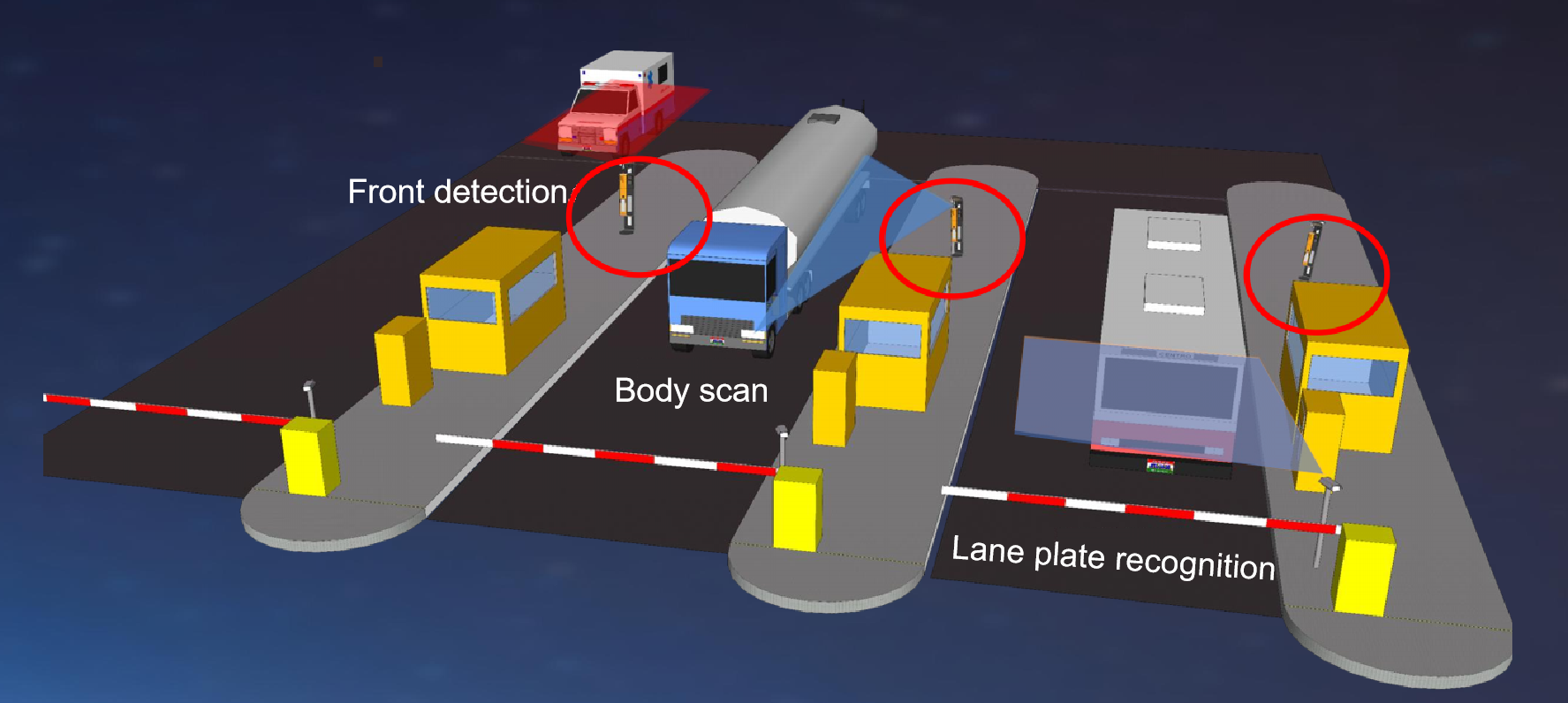

Este sistema se utiliza para detectar vehículos ilegales (las infracciones incluyen: modificación, sin licencia, cobertura, sobrepeso, exceso de edad, etc.)

Sistema de hardware

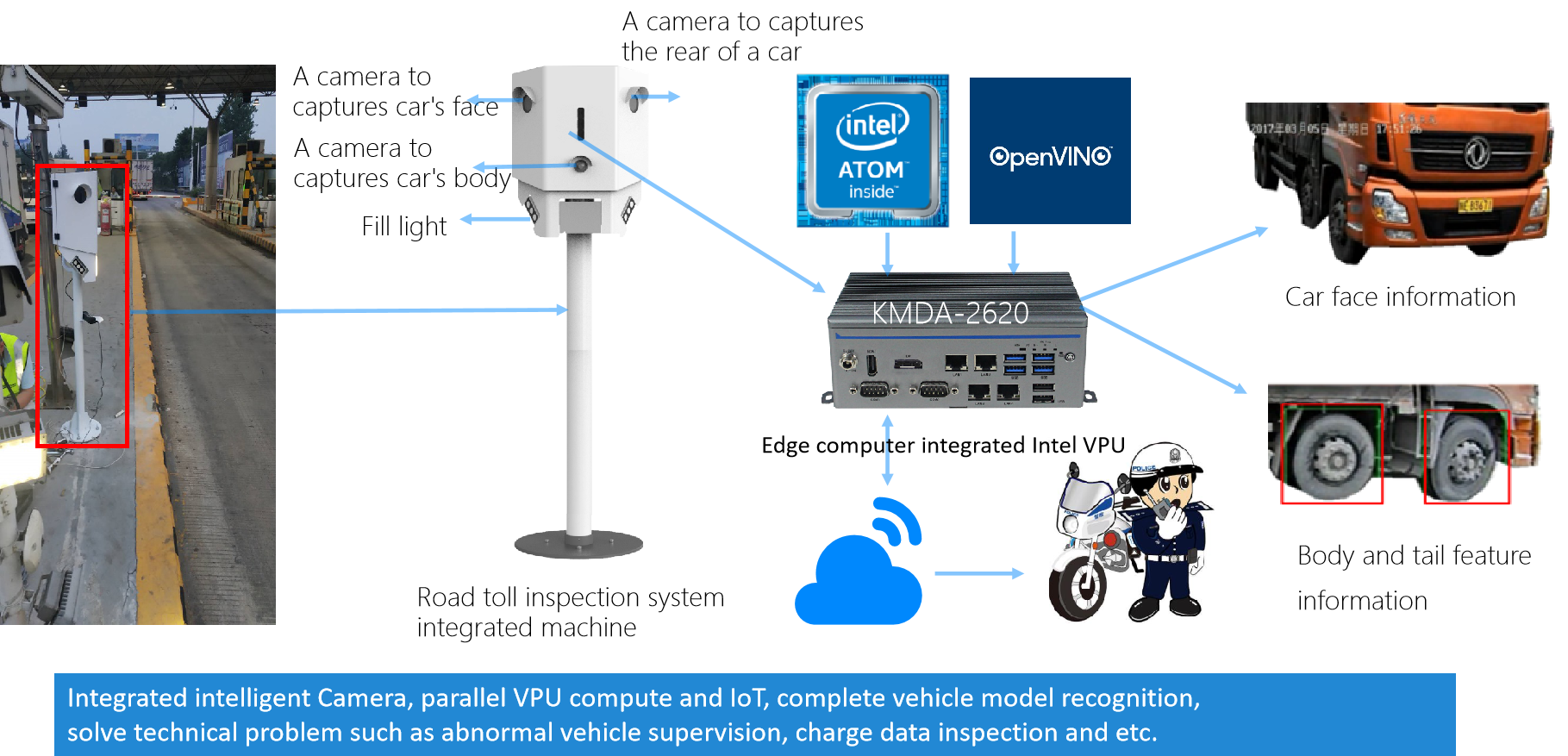

Rendimiento del producto

Reconocimiento de la cara del automóvil | Tasa de captura del vehículo ≥99% Tasa de reconocimiento de matrículas ≥98% |

Reconocimiento de la parte trasera | Tasa de captura del vehículo ≥99% Reconocimiento de matrículas Tasa ≥95 % |

Detección de carrocería | Tasa de captura de vehículos ≥99 % Eficiencia de unión ≥98 % |

Detección auxiliar | Tasa de captura de vehículos ≥99 % |

Dispositivo maestro | Identificación de vehículos ≥99 %; Reconocimiento de modelos de vehículos ≥98 % Medición de longitud ≥98 %; Detección de número de ejes ≥98 % Identificación de marca ≥97 %; Identificación de edad ≥95 % Reconocimiento de tipo ≥95 %; Reconocimiento de color ≥90 % |

CPU Intel®Skylake-S / Kabylake-S, 2 * LAN, 4 * USB3.0, HDMI, DP, VGA, 3 pantallas,10 * COM, 16 + 16-bit DIO, ranura de expansión PCIeX16 / PCI, DC-IN 12 ~ 24V.

KMDA-3920-ETC es un Box-Pc de alto rendimiento. Cuenta con CPU Intel® Skylake-S/Kabylake-S, memoria de doble canal 2*DDR4 2133/2400MHz, hasta 32GB. DP1.2+HDMI1.4b +VGA. 2*GbE LAN, 4*USB3.0, 1*Mini PCIe soporta 4G y Wifi/BT. 2*2.5» SATA HDD/SSD, 1*mSATA, 1*M.2, utilizado para almacenamiento,. Con amplia entrada de alimentación DC 12~24V, alto rendimiento, multi IO, ranura de expansión PCIe/PCI, fácil de desmontar e instalar tarjeta de función o HDD/SSD, ampliamente utilizado para Inteligencia Artificial, Video Seguridad, ITPS, peaje ETC y Visión artificial.

Intel® Whiskey lake U CPU, 2-CH DDR4, 1*HDMI, 1*DP, 5*G-LAN, 5*COM, 4*USB3.1 , 2*USB2.0, DC 9~36V

KMDA-3230 es un Box-Pc sin ventilador, Está equipado con la arquitectura Intel® Whiskey lake U. Está alimentado por la 8ª generación de procesadores Intel® core TM i3/i5/i7/Celeron serie U, 2-Ch DDR4, 2* SO-DIMM hasta 32GB.1*HDMI, 1*DP, doble interfaz de pantalla 4K,1*Line out&Mic interfaz de audio de alta fidelidad. No sólo tiene ricas interfaces I/O, sino también múltiples interfaces de extensión, 1*M.2 soporta NGFF-2230, y 1*Mini PCIe con 1*ranura para tarjeta SIM, soporta funciones inalámbricas 3G/4G /Wifi/ BT/ GPRS, y es fácil de extraer. 1*mSATA, 1*SATA3.0 para almacenamiento. Amplia entrada de energía DC 9~36V, el diseño de carcasa inferior de perfil de aluminio es bueno para la disipación de calor del disco duro. La máquina es pequeña, potente y delicada, adecuada para IOT industrial, visión artificial y otras aplicaciones.

CPU Intel® Celeron J1900, 2 LAN, 1 USB 3.0, 3 USB 2.0, 2 COM, CC 9~36 V, protección frontal IP65.

ALAD-A1001T es una PC de panel inteligente, integrada y sin ventilador, equipada con CPU Intel® Celeron J1900 y una pantalla LCD TFT de 10,1" de alto brillo con una resolución de 1280*800. Admite una pantalla táctil plana resistiva de 5 hilos y, opcionalmente, una pantalla táctil capacitiva proyectada multitáctil. Se utiliza ampliamente en logística y gestión de almacenes.